Client: DroneSystems ApS

DroneSystems are experts in drone-borne thermographic inspections, which is used to spot leaks in district heating supply. Their requirements for the sensor payload utilized for data collection are high and not always covered by commercial off-the-shelf (COTS) solutions. RotoWorks was tasked to solve an issue with the calibration of a thermal camera payload, which included design of a wind-protected and insulated camera housing to be mounted on a gimbal.

An Engineering Challenge

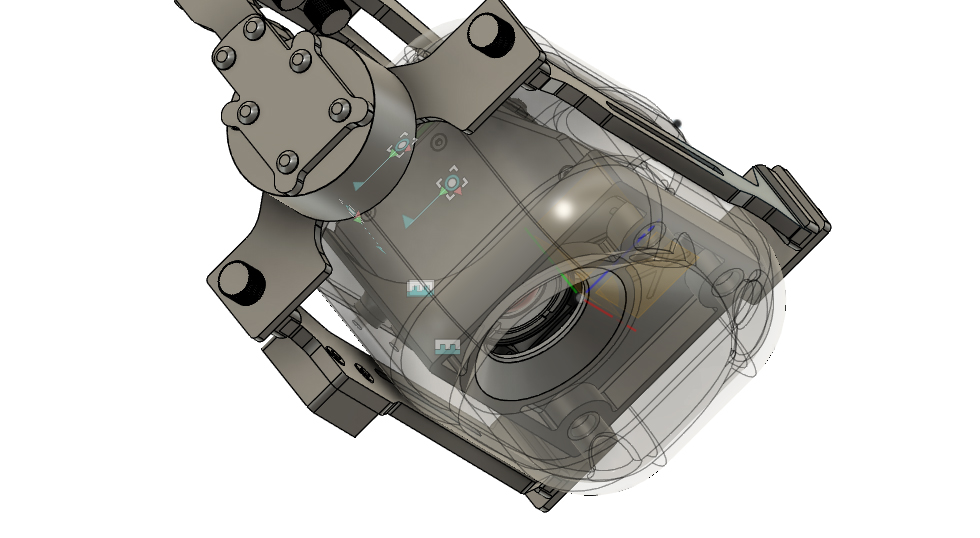

A large part of the design work revolved around the aerodynamic shape of the camera housing since vibrations caused by wind can degrade the data quality. The housing was thus designed with airflow coming from various directions in mind to minimize turbulent air and control flow separation, while also taking into account the heat dissipation from the thermal camera unit.

The housing was designed to be mounted on an existing COTS gimbal. Using available CAD models and drawings, the housing was made to fit perfectly and an analysis of weight distribution helped provide proper balancing for the gimbal.

Modularity Is Key

Another request from DroneSystems was the ability to switch between different thermal camera units in a quick and easy way. The camera housing was thus designed with a modular approach, meaning that both camera units could fit in the same housing with different inserts and a minimum of screws, making the change effortless.

Several functional end-products were 3D printed and delivered to DroneSystems, who finished it off with a beautiful red coating.